Ahmedabad

(Head Office)Address : 506, 3rd EYE THREE (III), Opp. Induben Khakhrawala, Girish Cold Drink Cross Road, CG Road, Navrangpura, Ahmedabad, 380009.

Mobile : 8469231587 / 9586028957

Telephone : 079-40098991

E-mail: dics.upsc@gmail.com

Additive Manufacturing

News: Recently, India’s first 3D printed post office was inaugurated at Bengaluru.

Background:

• The post office (Bengaluru’s Cambridge layout) was constructed in just 43 days, ahead of schedule, with technological support from IIT Madras and guidance from Professor Manu Santhanam.

What is Additive manufacturing?

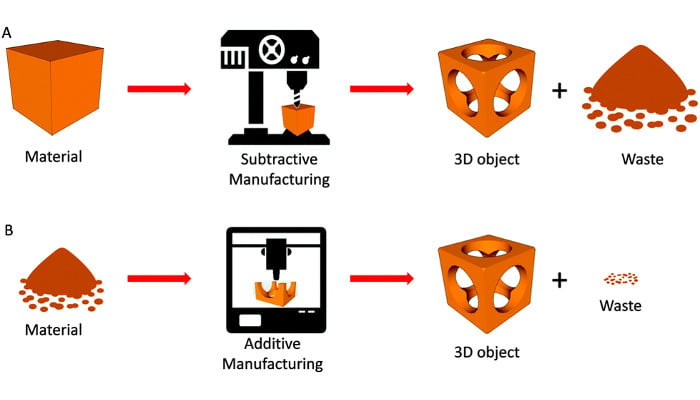

• Additive manufacturing is a process of creating an object by building it one layer at a time, using a digital design file and various materials. It is also known as 3-D printing, and it can produce complex shapes and structures that are not possible with traditional manufacturing methods.

• Additive manufacturing has many applications in different industries, such as aerospace, medical, automotive, and consumer products.

How does it work?

• In additive manufacturing, the process begins with a digital 3D model of the object to be produced. This digital model is sliced into thin

horizontal layers using specialized software.

• The 3D printer then follows these layers' instructions to deposit material, typically in the form of liquid resin, powdered metal, plastic filament, or other types of materials, layer by layer. Each layer fuses or solidifies with the previous one, gradually building up the final object.

What are the benefits of Additive manufacturing?

• Design Freedom - AM allows for the creation of highly intricate and complex geometries that are challenging or impossible to achieve using traditional manufacturing methods.

• Rapid Prototyping - AM facilitates rapid iteration and prototyping of designs, allowing engineers and designers to quickly test and refine concepts without the need for expensive tooling or long lead times.

• Customization - AM enables the production of personalized and customized products at a relatively low cost. This is particularly valuable in industries like healthcare, where patient-specific implants and medical devices can be created.

• Reduced Material Waste - Traditional manufacturing often involves subtracting material from a larger block, leading to significant waste. AM, on the other hand, adds material only where it's needed, minimizing waste and making it more environmentally friendly.

• Geographical Flexibility - AM technologies can be deployed in remote or challenging environments, making it possible to produce necessary components on-site without the need for extensive infrastructure.

What are different types of Additive manufacturing technologies?

• Stereolithography (SLA)

• Selective Laser Sintering (SLS)

• Fused Deposition Modeling (FDM)

• Binder Jetting

• Digital Light Processing (DLP)

• Direct Metal Laser Sintering (DMLS)

• Electron Beam Melting (EBM)

• Laminated Object Manufacturing (LOM)

• Continuous Liquid Interface Production (CLIP)

• Power Bed Fusion

What are the challenges of Additive manufacturing?

• Equipment Costs - The initial investment cost for high-quality AM equipment can be significant, limiting access for smaller businesses or individuals. Maintenance and repair costs can also be substantial.

• Quality Control and Standards - Ensuring consistent quality and dimensional accuracy across AMproduced parts is essential. The lack of standardized testing methods, material properties, and quality control processes can lead to variations in finished products.

• Speed and Scalability - While AM offers design flexibility, it can be relatively slow compared to traditional manufacturing methods, particularly for producing large volumes of parts. Improving printing speeds while maintaining high-quality outcomes is an ongoing challenge.

• Build Size and Resolution - The build size of AM machines can limit the size of parts that can be produced, and achieving high-resolution prints with large build volumes can be technically challenging.

• Regulatory and Certification Hurdles - In industries like aerospace and healthcare, AM-produced parts may need to meet stringent regulatory and certification requirements. Developing standards and ensuring compliance can be complex.

• Skill and Expertise Gap - Operating and maintaining AM equipment requires specialized skills and knowledge. There is a need for a skilled workforce capable of leveraging AM's potential effectively.

Way Forward

• The technology is in its nascent stage but it has lot of scope for our country and even the FM Nirmala Sitharaman suggested to use 3D-print technology to boost affordable housing in India especially under PM Aawas Yojana.

Address : 506, 3rd EYE THREE (III), Opp. Induben Khakhrawala, Girish Cold Drink Cross Road, CG Road, Navrangpura, Ahmedabad, 380009.

Mobile : 8469231587 / 9586028957

Telephone : 079-40098991

E-mail: dics.upsc@gmail.com

Address: A-306, The Landmark, Urjanagar-1, Opp. Spicy Street, Kudasan – Por Road, Kudasan, Gandhinagar – 382421

Mobile : 9723832444 / 9723932444

E-mail: dics.gnagar@gmail.com

Address: 2nd Floor, 9 Shivali Society, L&T Circle, opp. Ratri Bazar, Karelibaugh, Vadodara, 390018

Mobile : 9725692037 / 9725692054

E-mail: dics.vadodara@gmail.com

Address: 403, Raj Victoria, Opp. Pal Walkway, Near Galaxy Circle, Pal, Surat-394510

Mobile : 8401031583 / 8401031587

E-mail: dics.surat@gmail.com

Address: 303,305 K 158 Complex Above Magson, Sindhubhavan Road Ahmedabad-380059

Mobile : 9974751177 / 8469231587

E-mail: dicssbr@gmail.com

Address: 57/17, 2nd Floor, Old Rajinder Nagar Market, Bada Bazaar Marg, Delhi-60

Mobile : 9104830862 / 9104830865

E-mail: dics.newdelhi@gmail.com